Aluminium Frame Hot Pot

Product Details:

Aluminium Frame Hot Pot Price And Quantity

- 1 Unit

Aluminium Frame Hot Pot Trade Information

- Per Month

- 90 Days

- All India

Product Description

Other Details:

- 50KW/75KW/100KW/125KW

- 1000Hz/3000Hz

- 50KG/75KG/100KG/150KG/200KG/300KG

- Foundry/Lost wax casting

- Silver/Iron/Copper/Brass Steel/Aluminum

|

Size |

Brass 950 deg C (KG/HR) |

Copper 1100 deg C (KG/HR) |

Steel 1650 deg C (KG/HR) |

Iron 1485 deg C (KG/HR) |

|

50KW |

145 |

125 |

80 |

75 |

|

75KW |

220 |

195 |

112 |

125 |

|

100KW |

300 |

270 |

153 |

170 |

|

125KW |

387 |

350 |

195 |

216 |

ï

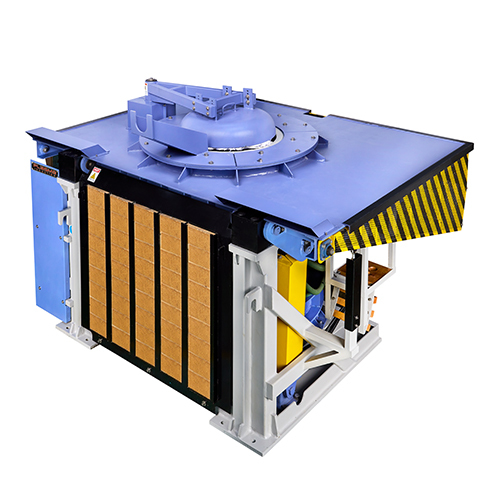

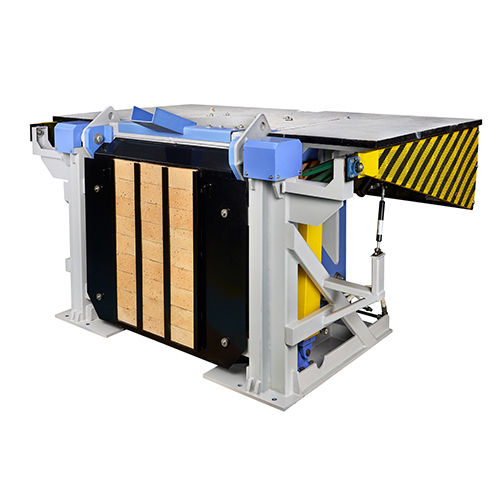

Hydraulic tilting mechanism for coreless melting furnace for housing and providing rigid support to the induction melting coil, constructed from aluminium alloy casted side wall. Top and bottom block manufactured by high alumina refractory with stainless steel fibre reinforcement.

Tilting mechanism by heavy duty hyd. Double acting cylinder set with flow control valves.

Leak detector assembly with stainless steel probe (Antenna) wires and hardware.

Water cooled power leads for connection between the induction coil and external bus bar.

Induction coil box mounted on heavy duty fabricated leg through the self-aligning pillow brass block.

Hydraulic operated cylinder cover.

Heavy box section aluminum frame structure.

Side guard to eliminate spillage of liquid metal material on hydraulic hose pipe.

Advance front guard with ceramic bricks.

Heavy brass bushing technology for tilting structure for long life.

Fluid control throttle valve.

Hydraulic operated lid cover.

Other Products in 'Hot Pot' category

GST : 24AAKCP5021H1ZM

|

PLASMA INDUCTION (INDIA) PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese